CPULD News, Spring 2023

FEATURE

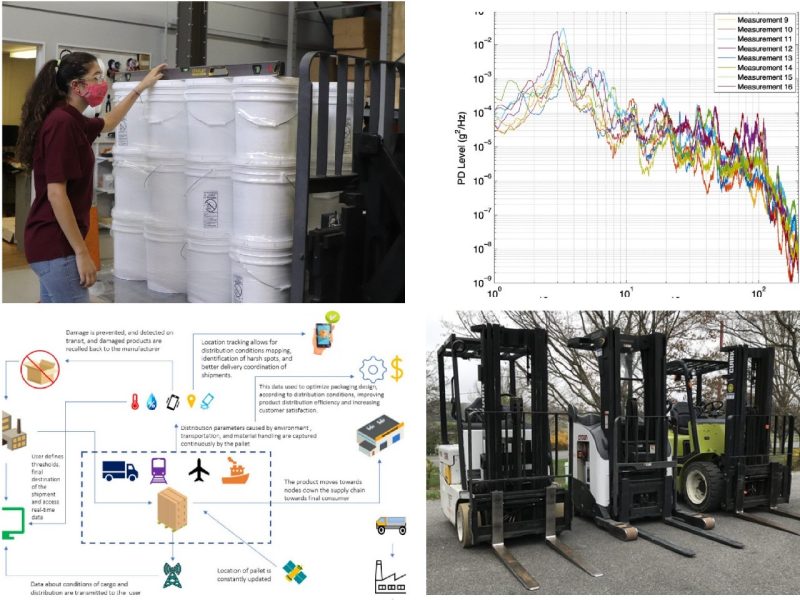

Measurement of Hazards Experienced by Pallets During Material Handling

Recently graduated CPULD alumni, Clark Sabattus (Master’s Degree, Arlington, TX), researched the Measurement of Hazards Experienced by Pallets During Material Handling for his Master’s project. The objective of this research project was to investigate the intensity of the vibration and horizontal shock impacts that forklifts exert on pallets during material handling. Although often overlooked, pallets can become costly for a company if not designed correctly for their specific supply chain. Forklifts are the dominant mode of material handling for palletized products, and they are responsible for the majority of damages experienced by pallets.

Despite the prominence of forklifts in the supply chain and their importance to pallet design, there is a lack of research focusing on the interactions between forklifts and pallets. It is important to be able to replicate what a pallet might experience in the field, so when testing in a laboratory setting, a company will be able to accurately gauge their pallet’s functional capabilities.

ALUMNI SPOTLIGHT

Tyler Matusevich, a local southwest Virginian, came to Blacksburg from just a few miles away in Radford, VA. “Having grown up in the New River Valley going to many Virginia Tech athletics games in my youth, I knew I wanted to officially be a Hokie. Additionally, it’s a great school known for innovation with a well-established College of Natural Resources and Environment. I was accepted into CNRE as an undecided major in 2009, but after talking to my advisor and taking the Intro to Packaging course that first semester, I declared my major.”

RESEARCH HIGHLIGHTS

Ecommerce packaging is driving packaging engineers to develop new, sustainable solutions and more convenient ways of shipping products throughout the world. It also affects material use; packages that are shipped need to withstand more hazards and be more protected when in transit. The responsibility of protective packaging has increased with the growth of ecommerce. Each characteristic is important to make sure products can be shipped worldwide while being protected to withstand risks.

The specific procedures used to test the heat pumps and air conditioning units followed the ISTA 3E standard which serves to mimic movements and stresses surrounding loading, full truckload shipping, and unloading individual packages. In real life, each step carries risks of drops and falls. The ISTA 3E standard is the perfect testing process to replicate the mechanical stresses, vibrations, and potential damage experienced by a package during shipment to and from distribution centers. Packaging systems that pass these tests can then be certified as such and utilized for global distribution.

To determine the strength of fasteners in joints on a pallet, it is generally necessary to conduct an incline impact test. While this method accurately predicts pallet performance, it is time-consuming and expensive. Fastener strength can be estimated by using data to mathematically predict performance. The purpose of this study was to identify a testing apparatus that could simplify testing the strength of the fasteners in pallet joints.

This study aimed to identify trends in cold chain packaging efforts as well as discover the materials and technologies used to successfully transport products at various temperatures. This project analyzed current trends and future innovations to cold chain processes. The researchers looked into various technological advancements and how they have been used to improve tracking temperatures and shipments. The goal was to create a methodology to use to research cold chain insulated-container performance.

Last-mile delivery for groceries has shown increased popularity in recent years. A 2019 study of U.S. residents taken during the Covid-19 pandemic showed 31% of respondents engaged in online grocery shopping. The objective of this investigation was to map and fully characterize the process packaged-goods experience from the moment they are picked up from a shelf in a grocery store to when they arrive at a consumer’s doorstep. An additional goal was the identification and evaluation of the potential hazards that may occur.

Although the load capacity of a pallet depends on a multitude of factors, the stiffness of the joints between pallet components has a major influence on overall pallet load capacity. Heavy-duty pallets are often assembled with alternative fasteners such as bolts and lag screws. Currently, the effect of these alternative fasteners on joint stiffness is not understood; this limits the use of these fasteners by the industry. Therefore, the objective of this research was to investigate the stiffness of pallet joints constructed using alternative fasteners such as bolts and lag screws.

GRAD STUDENT SPOTLIGHT

Sean Hobbs came to Virginia Tech from East Rockaway, NY. He graduated with his undergraduate degree in Packaging Systems and Design and moved directly into working on his Master’s degree in Forest Products, which he will finish in the fall of 2023. Sean has one older brother and prior to coming to VT, in high school, he played baseball and ran track. Here in Blacksburg, his favorite hobbies are practicing his guitar, fishing the local waterways, and playing pick-up basketball games with friends.

Research Updates

Although the vast majority of the pallets are repaired or recycled into secondary products such as mulch or boiler fuel, a portion of all pallets end up in landfills at the end of their useful life cycle. The purpose of this research is to investigate the total number of pallets and crates reaching landfills in the United States as well as to gain a better understanding of the overall waste stream.

This research project will collect data about the level of shocks and vibration experienced by packages transported throughout the South Korean parcel delivery system, particularly during last-mile delivery. This data will be compared to internationally used packaging testing standards in order to help develop a proposed testing plan for Korean e-commerce package testing.

CPULD Articles Published

Outside News

UPCOMING EVENTS

Contact Our Team:

Quotes for new testing projects, distribution packaging projects, unit load design projects, membership with the center, new research projects.

Ongoing testing operations, lab management, scheduling unit load and pallet lab deliveries, questions about lab management and work schedules.

Primary packaging design and packaging materials testing, scheduling deliveries of primary packaging materials, new research into primary packaging.

Corrugated materials design & testing questions, scheduling deliveries of corrugated materials. IKEA testing scheduling & questions

Any immediate needs, delivery times, locations, and info, invoicing questions, accounts receivable/ accounts payable inquiries.

Scheduling meetings with Dr. Horvath, short course & webinar info, center event plans, website & social media questions, marketing.