Leak and Seal Strength Testing

This test quantitatively determines seal performance, seal quality, burst pressure, compression resistance, torsion force, and joint/disengaging force.

This test can be performed on flexible packages, aseptic packages, various plastic pilfer-proof closures, flexible tubes, caps, as well as other materials. This test helps ensure that new primary packaging materials and are created to handle real-world situations.

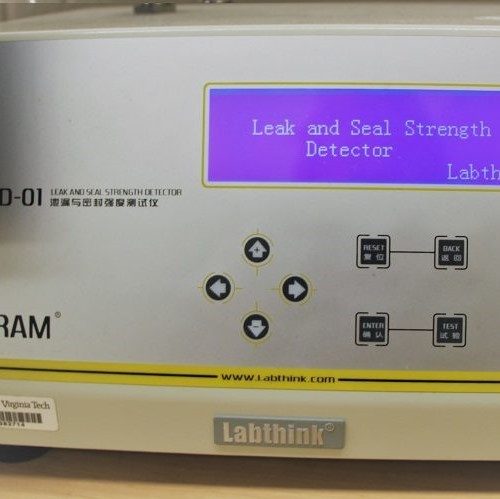

Leak and Seal Strength Testing: LabThink i-Leaktek 6600

Equipment used for Leak and Seal Strength Testing:

Leak and Seal Strength Testing: LabThink i-Leaktek 6600

Labthink:

i-Leaktek 6600

Test Range: 0-600 KPa; 0-87psi; 0-1.6MPa

Resolution: 0.1KPa

Test Accuracy: 0.1% FS

Temperature Range: -10C – 55C,

Humidity Range: 0 – 100%