Sustainable Packaging Materials Lab

Sustainable Packaging Materials Lab

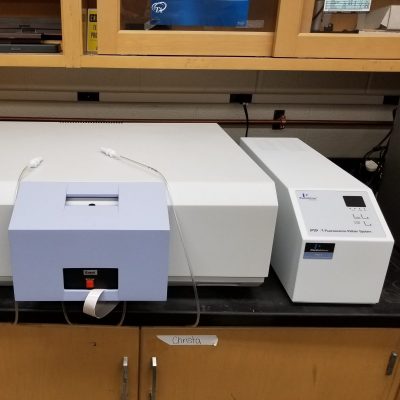

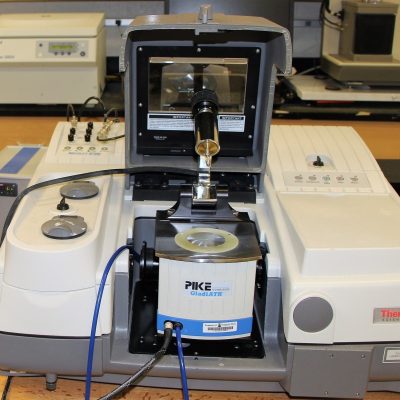

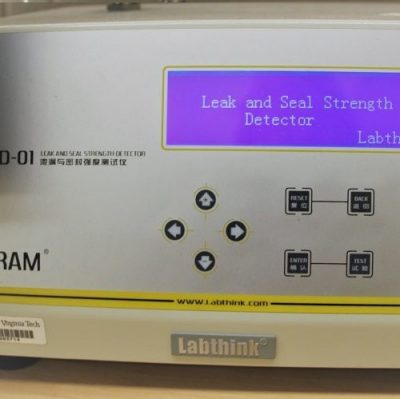

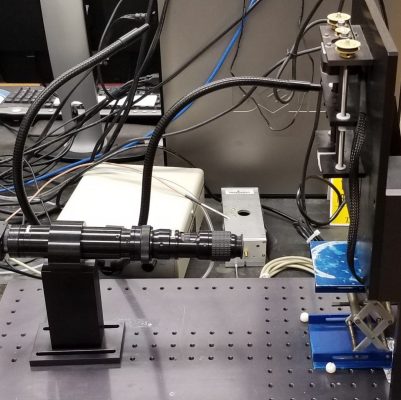

A Look Inside the Lab...

Product shelf-life is primarily dependent upon multidimensional interactions between packaging materials, packaging structure, and the products themselves. The Primary Packaging Laboratory provides diverse primary packaging testing services as well as research and development projects designed specifically to meet the needs of the primary packaging industry. The lab’s services are in high demand because the evaluation of existing and future products and systems is essential to both manufacturers and consumers. The constant development of new packaging materials and/or systems is highly demanded by our global society of fast moving consumer trends and cultural diversity.

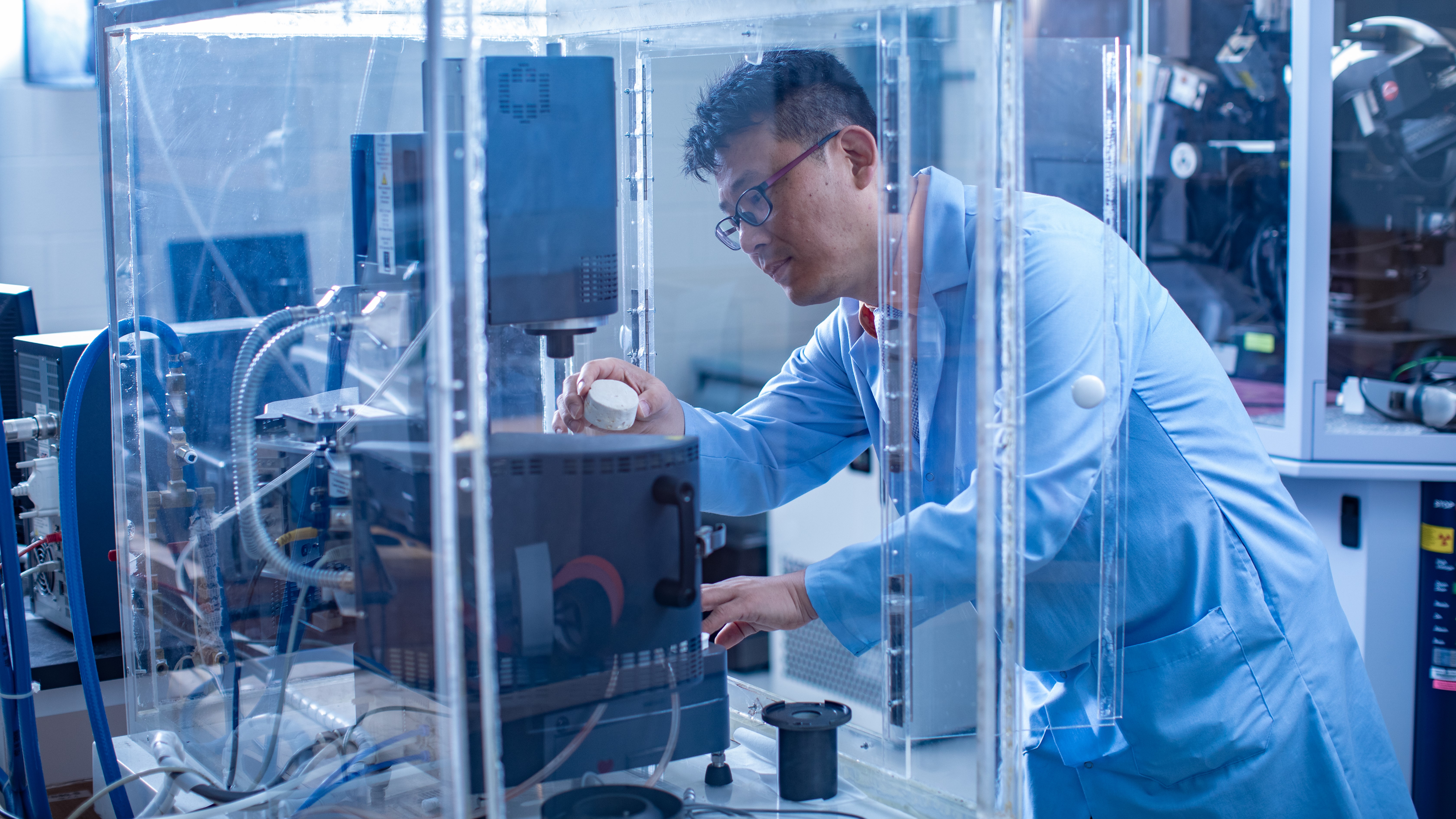

The research team is focused on developing and investigating the structure and functionality of new, composite, packaging materials. The team is researching both a variety of natural and synthetic polymers and the active agents such as antioxidants or antimicrobials derived from biomaterials. They are also studying the composite structures of carbon based nanomaterials and other inorganic nanomaterials. The extraction of biopolymeric materials from a biomass and its utilization in packaging has been funded by both government sources and private industry.

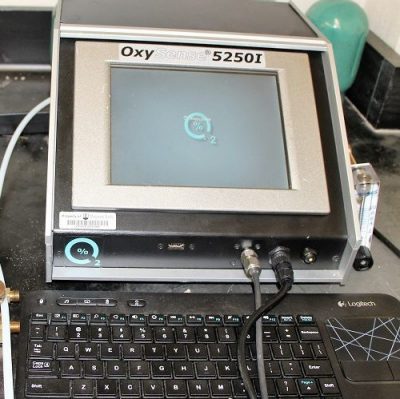

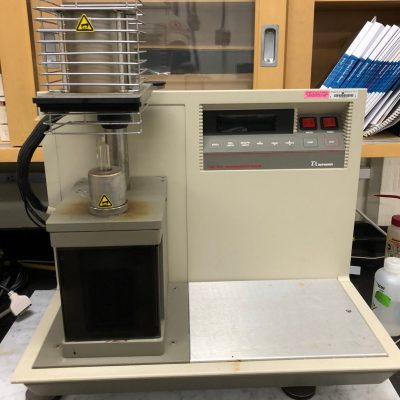

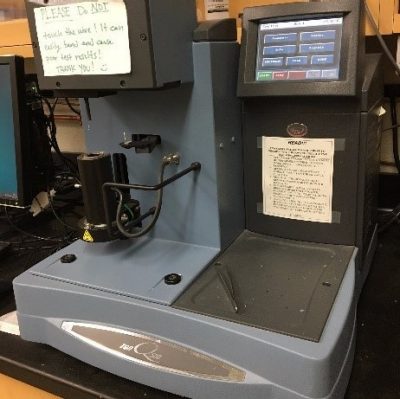

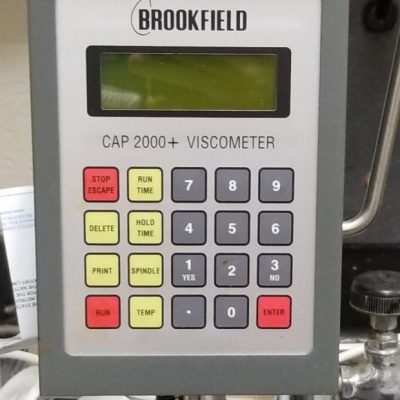

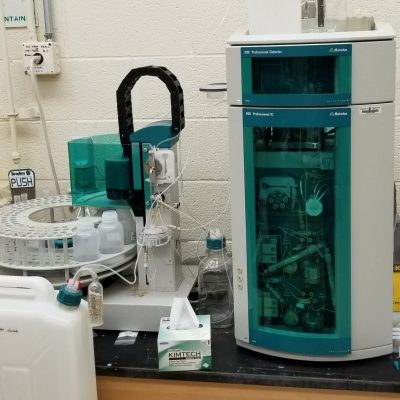

The lab’s team also provides third-party primary packaging materials testing services using official, standard ASTM, ISO or TAPPI methods. This includes packaging materials evaluation and analysis, as well as packaging structure development and packaging materials testing. Package testing, as well as package materials testing, are important parts of the research and development process. Testing helps ensure that new package designs and primary packaging materials are created specifically to handle real-world situations.