Pallet Fastener Testing

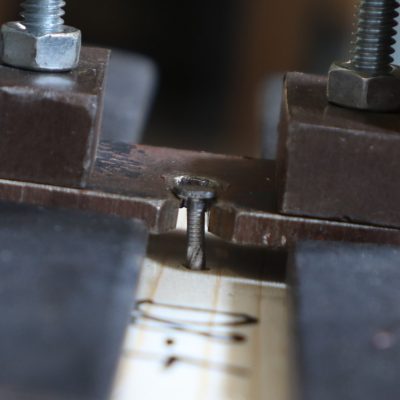

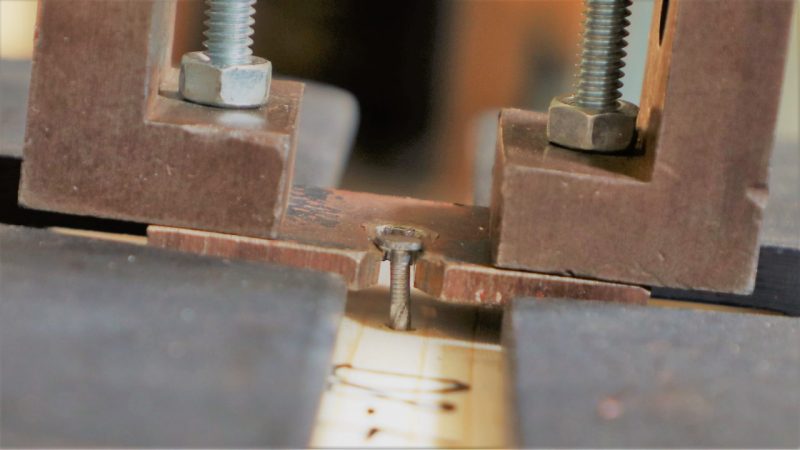

The evaluation of fasteners allows companies to comply with regulations. Fasteners are measured by length and width of the shank, angle and type of the thread, shape and size of the head. And, fasteners are tested for how much force it takes to bend them, and how much force it takes to pull them out after they’ve been driven into any particular substance (wood, metal, plaster, etc…). The more force that it takes to bend or pull the fastener, the stronger that fastener is, which in turn leads to a stronger finished product.

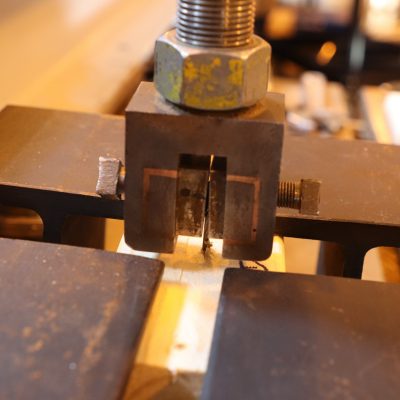

The Morgan Impact Bend Angle Nail Test (MIBANT) evaluates fastener quality to predict the fastener properties while in use. Other fastener tests include the Fastener Quality Analysis (FQA), which provides information about the effectiveness of the investigated fastener on the durability of the pallet.

Fastener tests provide information about compliance with ANSI MH1. The FWI (Fastener Withdrawal Index) and FSI (Fastener Shear Index) are calculated as described in ASTM F680. Additional performance evaluations include actual withdrawal/shear/head pull through resistance of nailed joints. These tests follow ASTM D1761.

Learn more about the various tests performed for Pallet Fastener Testing below: