Research Highlight: Investigating the effect of pallet deckboard thickness on the compression strength of plastic pails

The objective of this undergraduate project conducted during the spring 2021 semester was to measure how pallet deckboard stiffness affected pail compression strength in a unit load. Testing was conducted using the ASTM D642 guidelines combined with custom-made pallets, 5-gallon plastic pails, and an MTS testing machine.

Three undergraduate students were selected to conduct this research project. Victoria Dashevsky graduated in May 2021 and was from Alpharetta, Georgia (Image 2). Jordan Wells, a senior from Roanoke, Virginia, and Cameron Fischi both also worked on this project (Image 3). This research was supported by the National Wooden Pallet and Container Association for use in their unit load design software.

A considerable variety of containers are transported using pallets in global markets. Although, corrugated boxes are the most commonly transported packaging types, pails are commonly used to transport smaller quantities of liquid for industries. The main pail user industries include food, paint, and chemicals. The pail industry is projected to grow in their market at a high rate of 4.7% by 2027. Additionally, industrially used pails are predicted to reach an overall market value of $9.82 billion in the same timeframe. The most common pail design in the supply chain is the 5-gallon open-headed plastic pail. Pallet software cannot be used to properly evaluate the effect that pallets have on pails as this interaction has never been studied before. Due to their frequent use in distribution channels, it is important to fully understand how pallets interact with pails.

The main objective of the study is to investigate how pallet stiffness affects the strength of plastic pails using 2” double overhang and two different pail locations (center and edge) (Image 1). Two wooden pallet simulators were constructed for testing purposes. The pallet simulators were simulating a 48” x 48” stringer-class pallet design that is commonly used to transport pails. The pallet simulators were made from defect-free, southern yellow pine and had overall outer dimensions of 23.5” x 36”. All deckboards were spaced evenly, and four different deckboard thicknesses were investigated: 3/8”, ½", 5/8” and ¾". The pails used for testing were 5-gallon open-headed plastic pails (Uline model S-7914W). They were constructed from High Density Polypropylene (HDPE), and their wall thickness was .090”.

The test procedure was conducted according to the guidelines of ASTM D642. An MTS universal testing machine equipped a 5,000 lb. load cell was used for the testing. The pails were loaded using a custom loading jig manufactured from the bottom section of a pail reinforced with plywood to mimic the interaction between stacked pails (Image 5).

The samples were loaded until visual failure of the pail (such as buckling [Image 4]) and/or a ~10% decline of the load curve was observed. The load and deflection were collected using a digital data acquisition system. Ten pails were tested on a rigid support to provide a baseline. Then, ten replicates of each condition (center and edge for each deckboard thickness) were tested and used to calculate the average values for each.

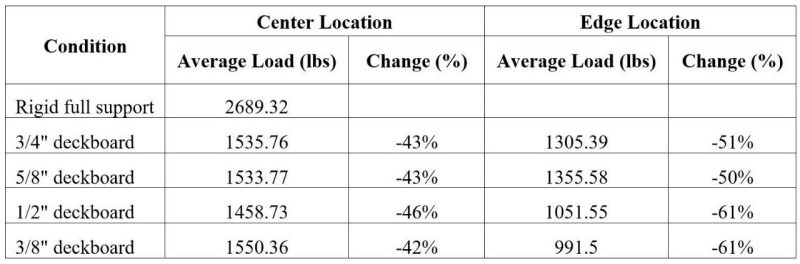

The results of the investigation are presented in Table 1.

The data was analyzed to show general trends across the location conditions. After the statistical analysis it was found that there was a significant reduction in pail strength for all deckboard thicknesses. However, decreasing the deckboard thickness did not have an effect on the results for the Center condition and only had a slight effect for the Edge condition. In addition, the strength of pails supported at the edge of the pallet where one side of the pail was on the stringer and the other side was on the deckboard, reduced as much as 37% compared to the pails that were supported on the Center for the pallet. Similar findings were found by Quesenberry et al. for corrugated boxes. The current results further validate that when packages are asymmetrically supported, the effect of deckboard stiffness has a more prominent effect of their strength.

The major conclusions from this research study include the following:

- The average of strength of 5-gallon open-headed plastic pails is around 2,700 lb.

- The strength of pails supported asymmetrically on the edge of the pallet decreased with the decreasing deckboard thickness.

- The mode of failure for the pails supported on the edge was the bucking of the side that was on the top of the stringer.

- The variation in deckboard thickness had no effect of the pail strength when the pails were centered on the pallet.