Improvement Projects Recommended for ISO Accreditation of the Corrugated Materials Testing Lab

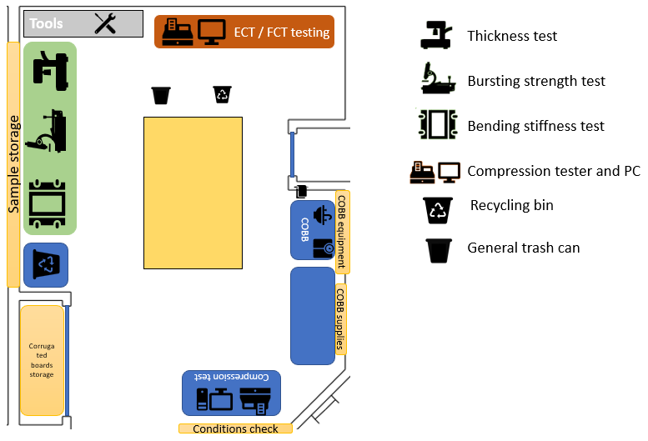

Jorge Masís came to Virginia Tech as an undergraduate student intern while completing his bachelor’s degree at the Industrial Production Engineering School in Costa Rica’s Institute of Technology. His graduation project was developed to help the CPULD’s Corrugated Materials Testing Lab (Image 1). The purpose of the project was to develop a series of improvements involving the lab’s resources, structure, personnel, and management systems that would eventually allow the lab to be accredited under the International Standards Organization’s standard 17025:2017 (referred to hereafter as ISO 17025) guidelines.

Compliance with industry standards and norms is important for CPULD, as it proves that its operations are confidential and impartial while guaranteeing that the lab has the technical capabilities to produce consistently high-quality results. CPULD is committed to assisting its collaborators, customers, and suppliers in creating better pallets and packaging and helping to improve efficiency in material handling. It also values its contribution to the student community, aiming to provide experience in the real-life development of systems-based packaging designs.

The first step in Masís’ project was to describe the general corrugated materials testing process and identify the role of each individual in the lab. The scope of compliance was then determined based on the lab’s most important tests, customer demands, or economic benefits. As every laboratory is different, it was important to determine which ISO clauses would be followed for the Corrugated Materials Testing Lab. Looking for needed improvements without first understanding the laboratory would have delayed the project. Once the scope and applicable clauses were determined, the assessment could start. The goal of the assessment was measuring the degree of compliance of the lab’s current processes, which, in turn, would help identify the gaps where the lab didn’t meet the requirements of ISO 17025.

The compliance assessment began with an initial diagnosis, done through a series of checklists, as well as a time-and-motion study. The checklists included all applicable clauses of ISO 17025 and a box to check if the laboratory complied with the requirements. The checklists involved looking into the laboratory’s management systems, processes, resources, and general ways of managing impartiality and confidentiality, and comparing them all against the demands of ISO 17025. Through analysis of the checklists, it was found that the lab’s average level of compliance already stood at 62%.

Masís then conducted a time-and-motion study, beginning with a brief description of the lab’s current operations and highlighting areas needing improvement, which were found through interviews with the laboratory management and researcher involvement in daily activities. The time-and-motion study estimated the average time dedicated to each step in the testing process. Masís looked at the physical arrangement of equipment and stations in the workplace and how intuitive and smoothly they allowed work to flow (Image 2). He also conducted studies on the physical motions needed to conduct each test in order to determine if any time or motion could be saved by conducting the tests differently (Image 3).

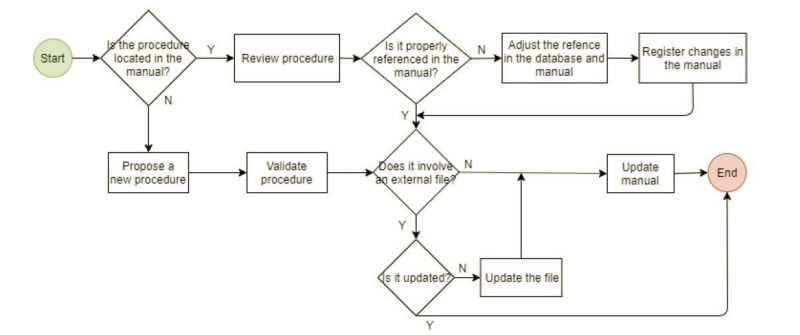

The main solution that Masís proposed for the Corrugated Materials Testing Lab was to create an overall laboratory manual that would spell out all lab procedures and testing processes. This manual would solve most of the compliance issues found; the main solutions proposed involved changes to the management systems already in place and documentation of the processes and resources in the lab. Other main focuses of the recommendations related to the labeling process and personnel competency tracking methods. All improvements were aimed at saving time and money and increasing efficiency in the lab (Image 4).

The laboratory manual that Masís wrote is currently under revision by management, as is a new storage folder arrangement that he proposed. The expected benefit for the lab is presented as better documentation of tasks through the use of datasheets for equipment, personnel competence, and resources in the laboratory. After the various sections in the manual have been accepted, their use will be tracked with a compliance indicator. The 62% level of compliance found in the laboratory in the early stages of the study is expected to rise to at least 80% within the first year.

Solutions proposed for the labeling issue include using an ink stamp instead of hand-labeling each corrugated sample. The ink stamp proposal represents an important new tool that could benefit the laboratory in terms of saving time during testing activities. The different methods tested during the solution proposal stage constituted a base in which management was able to determine the best option for the lab; factors such as stamp price, manufacturing capabilities, and ease of use came into play.

The improvements made to personnel tracking in the lab aimed to improve the process in two main ways: competency tracking and producing efficient results. The new scheduled testing schemes and using less material (i.e., sharing samples for each test) will save time for the technicians without compromising the results. This will help address the main problem with the current system, which is the ability to obtain results in a timely manner. As part of these round-robin improvements, management expressed interest in using a whiteboard to keep track of personnel and test completion. This presents a good approach in improving the methodologies used in the lab while also benefiting communication regarding testing activities, duties, and goals.

Masís’ project report (Image 5), taking into consideration the economic weight of the accreditation process, recommended that the Corrugated Materials Testing Laboratory opt for a trial period in which the demands in the new manual are fulfilled, monitored, and documented prior to further investment in the ISO 17025 accreditation. As the gathered information is recorded, it will serve as evidence of whether or not the accreditation would be economically beneficial, which will facilitate the decision of which path is best for the laboratory.