Research

Student studying sensor data for research project

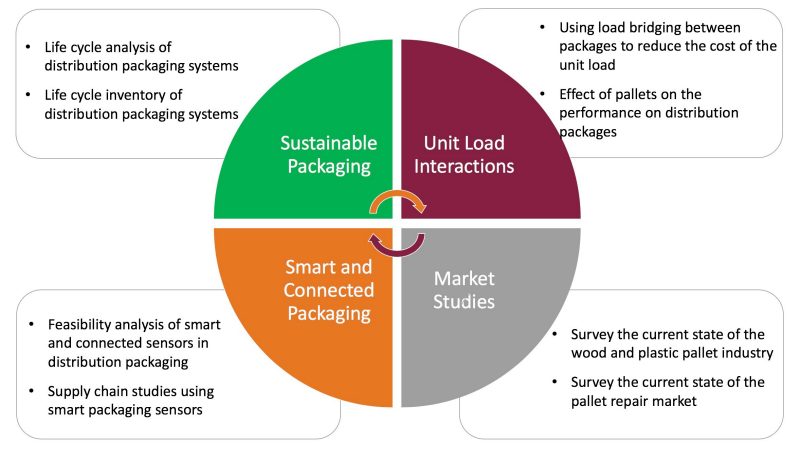

CPULD’s research areas are driven by the needs of the packaging industry and society. Our research team focuses on a wide range of projects, including:

- Developing of new ways to optimize distribution packaging systems and unit loads by using physical interactions between components

- Quantifying and improving the sustainability of distribution packages through the development of life cycle inventories and conducting life cycle analysis

- Conducting feasibility studies and supply chain analyses using the latest technology in smart and connected packaging

- Conducting market studies of the distribution packaging sector

Most projects are conducted through our Industrial Affiliate Membership Program; however, Sponsored Research projects are also available for more individualized research.

In addition to current research projects, CPULD maintains an extensive research database that includes articles on subjects such as: the performance of driven fasteners and observations of the damage frequency and severity levels occurring in pallets. Our pallet data, in particular, is vital to researchers developing reliability-based models of pallets, containers, and other such related structures.

Diagram showing all areas of CPULD research.

CPULD Published Papers:

- Navarro - 2022 - Design of an IoT system for the palletized distribution supply chain with model-based systems engineering tools

- Masis - 2022 - The effect of forklift type, pallet design, entry speed, and top load on the horizontal shock impacts exerted during the interactions between pallets and forklifts

- Alvarez Valverde - 2022 - The effect of wooden pallets characteristics on the compression strength of palletized plastic pails

- Alvarez Valverde - 2021 - The effect of plastic pails on pallet deflection and pressure distribution for stringer class wooden pallets

- Kim - 2021 - Investigation of the effect of pallet top-deck stiffness on corrugated box compression strength as a function of multiple unit load design variables

- Molina - 2021 - Development of a gaussian process model as a surrogate to study load bridging performance in racked pallets

- Molina - 2021 - Development of a friction-driven finite element model to simulate the load bridging effect of unit loads stored in warehouse racks

- Shiner - 2021 - An investigation of wood pallets landfilled and recovered at US municipal solid waste facilities

- Huang - 2021 - Vertical random vibration test spectrum to simulate forklift handling environments

- Huang - 2021 - Measurement and analysis of industrial forklift vibration levels for unit load testing purposes

- Morrissette - 2020 - Investigation into the load bridging effect for block class pallets as a function of package size and pallet stiffness

- Quesenberry - 2020 - The effect of pallet top deck stiffness on the compression strength of asymmetrically supported corrugated boxes