Oxygen Permeability Testing

Oxygen barrier property is a key to a packaging systems ability to protect its products from oxidation. Oxygen permeability may vary with temperature, humidity, pressure, and specimen thickness.

Our OxySense equipment can also be used for non-invasive and invasive measurements of oil, water, and air and permits multiple measurements over time on the same package.

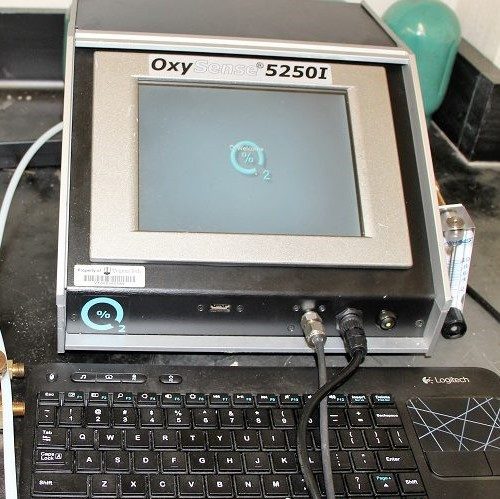

OxySense: Model 5250i

Equipment used for Oxygen Permeability Testing:

OxySense: Model 5250i

OxySense: Model 5250i

Lower Detection Limit: 0.03% 15ppb

Operating Temperature: -10C – 70oC

Operating Humidity: 0 -100%

Response Time: 1 Second